-

The 80G high-frequency flat flange mounted radar level gauge is a high-precision device in the field of industrial liquid level measurement. It adopts 80GHz high-frequency microwave technology and flat flange mounting structure, combined with non-contact measurement principle, to achieve accurate liquid level monitoring in various complex working conditions.

-

Advantages of High-Frequency Technology: Compared with traditional 26GHz radar, the 80GHz frequency band has a narrower beam angle (usually ≤3°) and stronger energy concentration. It can effectively avoid interference from obstacles such as agitators and ladders in the container, and maintain stable measurement even in small-diameter storage tanks or complex working conditions.

-

-

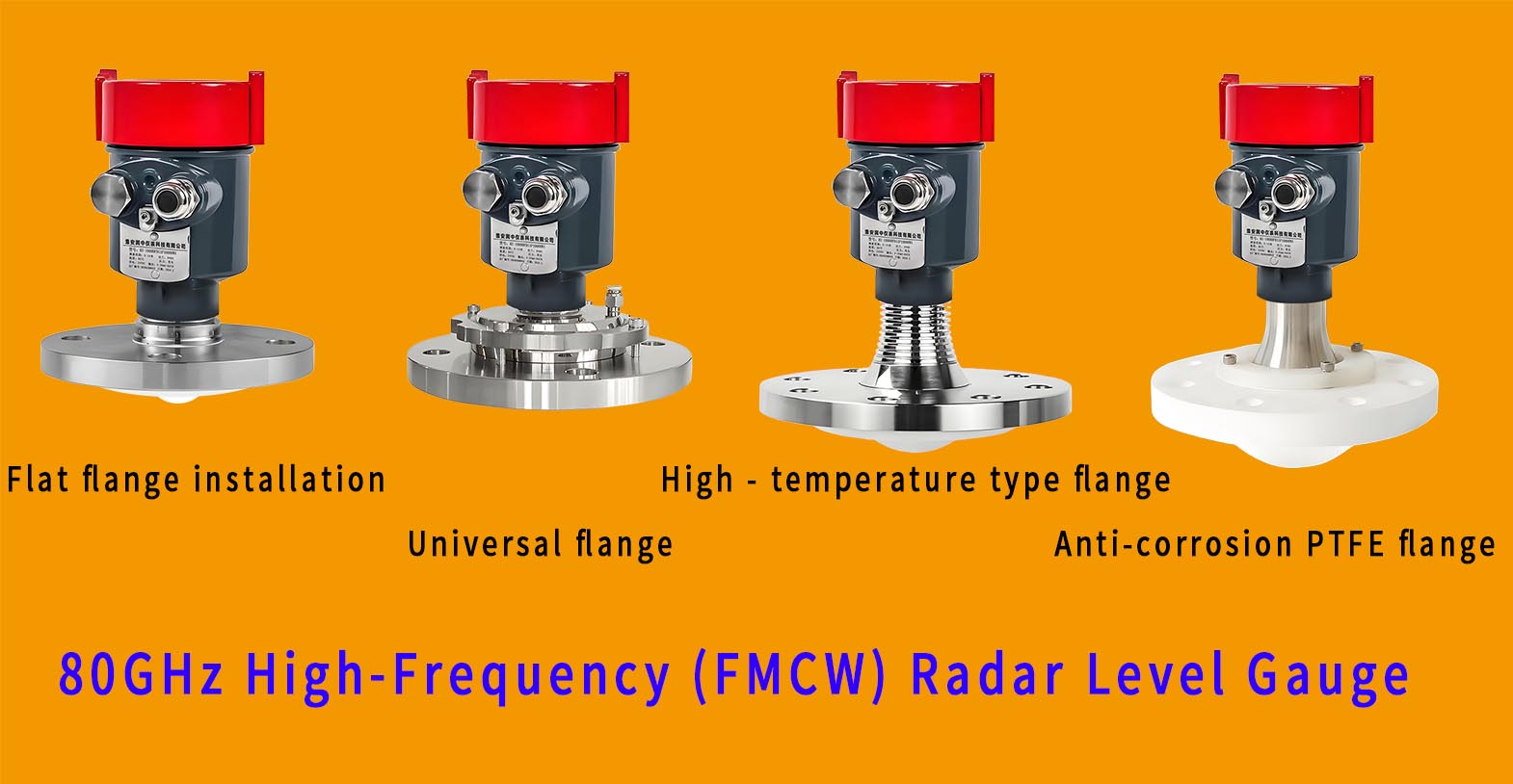

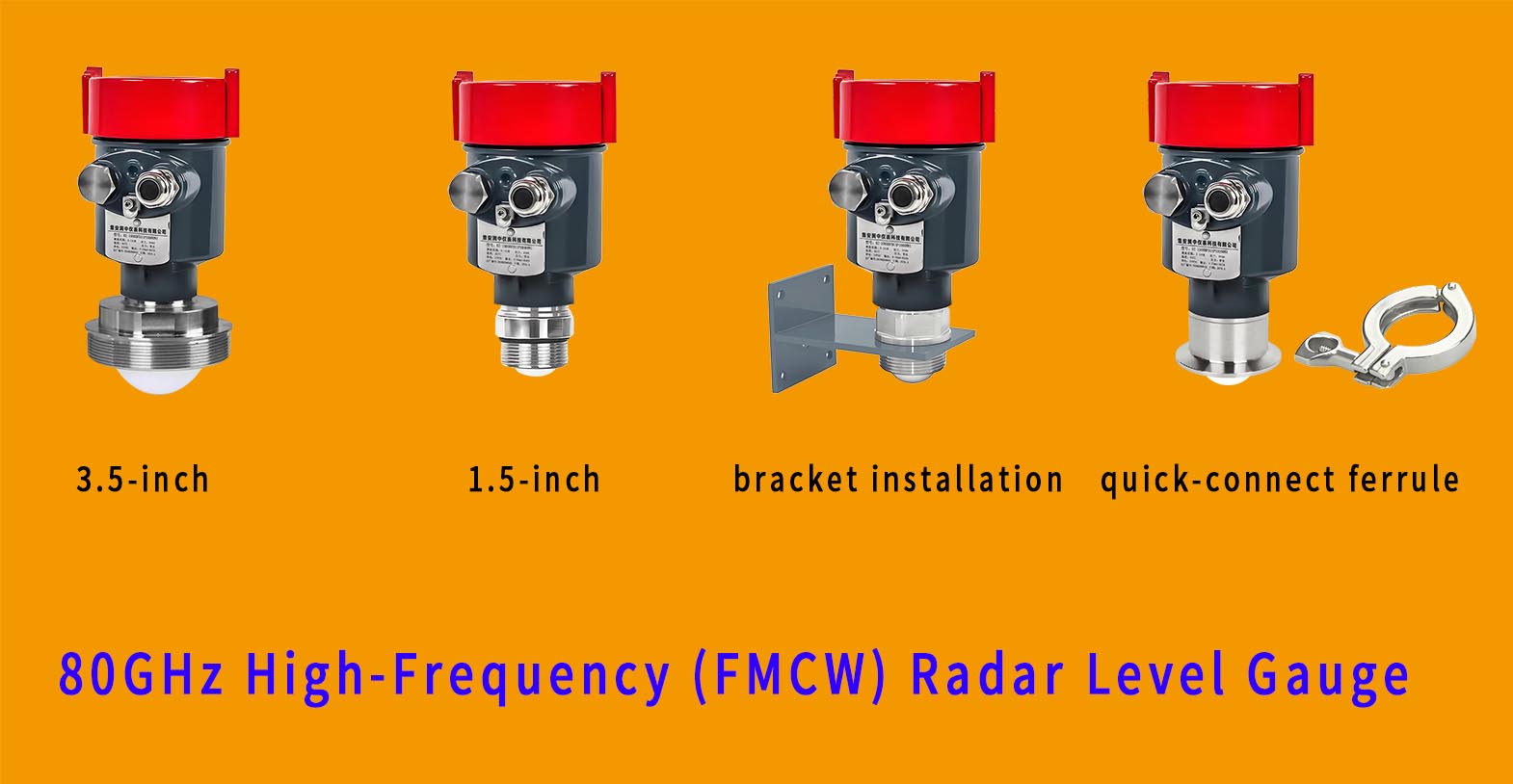

Flat Flange Mounting Design: It is connected to pipelines or containers using standard flat flanges (such as PL type slip-on flanges), featuring convenient installation and excellent sealing performance. It is compatible with various flange sizes from DN50 to DN200, and is especially suitable for high-pressure and corrosive medium scenarios (such as chemical reaction kettles and acid-base storage tanks).

-

Anti-Interference Capability: The non-contact measurement method is not affected by medium viscosity, density, foam, dust, and temperature and pressure fluctuations. The built-in advanced signal processing algorithm can automatically filter false echoes, ensuring measurement accuracy in harsh environments such as steam and volatile substances.

-

Wide Applicability: It is suitable for measuring the level of liquids (such as crude oil, acid-base liquids, water), slurries, and some solid particles. It covers industries such as petrochemicals, pharmaceuticals, food processing, and water treatment, and is particularly suitable for scenarios with limited installation space and high requirements for measurement accuracy.

II. Key Technical Parameters

|

Parameter Category |

Specific Indicators |

|

Measurement Range |

Standard type: 0.3m-30m; Enhanced type: up to 0.3m-50m (distance from empty tank to full tank) |

|

Measurement Accuracy |

±2mm (under normal working conditions), ±5mm (under complex working conditions, such as strong steam and high-viscosity media) |

|

Operating Frequency |

80GHz (K band), microwave pulse width ≤1ns |

|

Beam Angle |

≤3° (standard antenna), small-diameter antenna can be as low as 2° |

|

Flange Specification |

Compatible with standard flat flanges (PL type) such as DN50, DN80, DN100, DN150, with pressure rating PN16-PN100 |

|

Operating Temperature |

Antenna part: -40℃~+250℃ (high-temperature type optional +300℃); Electronic unit: -30℃~+70℃ |

|

Operating Pressure |

Vacuum to 40bar (special models can be customized up to 100bar) |

|

Output Signal |

4-20mA analog signal (with HART protocol), RS485 (Modbus RTU), relay output (2 channels optional) |

|

Explosion-Proof Rating |

Ex d ia II C T6 Gb (flameproof + intrinsic safety), suitable for Zone 0/1/2 hazardous areas |

|

Protection Rating |

Antenna housing IP68, electronic unit IP66 |

|

Material |

Antenna: 316L stainless steel (corrosion-resistant), Hastelloy optional; Flange: carbon steel or 316L stainless steel |

|

Power Supply |

24VDC (18-30VDC), power consumption ≤2W |

III. Installation and Maintenance

-

The installation position should avoid obstacles in the tank and turbulent areas of the feed inlet, and it is recommended to be at least 300mm away from the tank wall;

-

When installing the flat flange, ensure the sealing surface is flat, and gaskets (such as PTFE, metal wound gaskets) can be used to enhance sealing;

-

It supports online calibration and remote debugging. Parameter settings can be quickly completed through a HART handheld device or upper computer software, with a long maintenance cycle (mean time between failures ≥100,000 hours).

This model, combining high-frequency technology and flange installation, ensures measurement stability while taking into account the convenience of installation and corrosion resistance in industrial scenarios, making it an ideal choice for liquid level measurement in complex working conditions.

- Huai'an Runzhong Instrument Technology Co., Ltd All Rights Reserved